Copyright Protected

![]()

- Details

The taxonomic status of a microorganism can change following genomic studies. You can keep up to date with taxonomy using the Taxonomy Browser at https://www.ncbi.nlm.nih.gov/Taxonomy/Browser/wwwtax.cgi. An excellent resource. There have been major changes in the classification of lactobacilli. Authors should use the Online tool at http://lactotax.embl.de/wuyts/lactotax/ to ensure they use the correct genus for Lactobacillus species. Currently, this tool provides more information on lactobacilli than the Taxonomy Browser.

- Details

The sodium-to-salt converter and the recommended maximum daily intake of salt for infants, children and adults have been updated. The calculator now reflects current UK Governmental nutritional advice. Some software errors have also been corrected and the calculator is now working correctly.

- Details

Food technologists and microbiologists generally have limited information on the effect of temperature on the D-values of pathogenic and spoilage organisms. It is often necessary to model the D-value at a higher or lower temperature than the reference value.

This can be done in two ways, using the Bigelow (1921) method or the Arrhenius equation. The most commonly used method is the Bigelow method.

An article "Predicting the effects of temperature on the D-value calculated using the Bigelow and Arrhenius methods" has been added to the website. This provides an introduction to a free calculator for determining the Decimal Reduction Time (D) for a microorganism at a higher or lower temperature knowing the D-value at the reference temperature and the Z-value. The calculator compares the D-values obtained by the Bigelow and Arrhenius models and also gives the activation energy (Ea) and inactivation rate(ko).

- Details

I was honoured and delighted to receive the Society of Dairy Technology Gold Medal award at the Societies’ 80th Anniversary Conference: Digitalisation of Processing in the Dairy Industry at University College Cork on the 23rd of November.

The medal presented by the SDT President Mr Nick Edwards is awarded for outstanding contribution to dairy science and/or technology throughout the world. It was first awarded in 1951 and there have only been 17 awarded since that date. Only 3 per decade are allowed to be awarded, the last being to Dr Adnan Tamime in 2011.

The SDT gold medal was presented by Mr Nick Edwards

The presentation in the historic Aula Maxima at UCC was even more poignant since I started my dairy science and technology journey at this university working on lactococcal bacteriophages with Professors Charlie Daly and Pat Fox. My time at UCC left a lasting hugely positive impression of the institution and its staff.

A major element of this award was my work on the International Journal of Dairy Technology. The success of the journal is due in large part to the work of my editorial colleagues Dr Aprea, Professor Cruz, Dr Datta, Dr Li, Professor Mehta, Dr Rico and Ms Sarah Mellor, Ms Katy Griffiths, Ms Nelissa Duarte, Ms Keerthana Govindarajan, Mr Craig Gregory, Mr Jebasingh Duraisamy, Ms Ella Liu and Mr Noel McGlinchey at Wiley.

- Details

I was delighted to present a paper “Validating the microbiological safety of an HTST process for commercial ice cream manufacture at the 10th China Dairy Science and Technology Conference at Changchun, China held from the 3rd to the 5th October, 2023.

The conference was organised by the Chinese Association of Animal Products Processing and Jilin University and was held at the Jilin University.

I appreciated the kind and generous invitation from the Chinese Association of Animal Products Processing and Jilin University to be their guest in Changchun Province and to attend the Conference. Regretfully this was not possible on this occasion and I very much appreciated the opportunity to make the presentation Online. Special thanks to my International Journal of Dairy Technology (IJDT) colleague Dr Mohan Li for the invitation to present a paper at the Conference.

Dr Li took the opportunity to publicise the IJDT and a Special Issue of the IJDT on Chinese Dairy Science and Technology. Dr Li was aided in this project by Ms Ella Liu from Wiley, Prof. Dr Tiehua Zhang from Jilin University (also a Guest Editor), Prof. Dr Juncai Hou from Northeast Agricultural University (also a Guest Editor), Dr Cuina Wang from Jilin University, Mr Jun Wang from Jilin University, Dr Mengxue Diao from Jilin University and Dr Li Ren from Jilin University.

- Details

Dr Tomas Skoglund has derived a simple relationship between z-value (Bigelow method) and activation energy (Arrhenius model) that enables the z-value, a term used in microbial thermal death time calculations, to be corrected to comply with Arrhenius kinetics.

I have produced a free On-Line calculator to enable users to see the difference in Fo values obtained by using either method in UHT processing.

For the first time students, engineers and food technologists can easily see the differences in Fo values calulated using either method.

- Details

Over the next few months I will give readers the option of comparing F and D-values calculated using the Bigelow and Arrhenius methods. The first calculator can be accessed here. This facility enables technologists, microbiologists and students to readily compare the D-values calculated using both methods and by dividing the F-value by the D-value for target organisms to calculate the number of log reductions.

- Details

The paper “A narrative review of vitamin K forms in cheese and their potential role in cardiovascular disease” is the Editor's Choice article for the November issue of the International Journal of Dairy Technology (IJDT).

The article authored by Sitong Zhou, Bhavbhuti Mehta and Emma Feeney is a result of a collaboration between the UCD Institute of Food and Health, University College Dublin, and the Dairy Chemistry Department, SMC College of Dairy Science, Kamdhenu University, India.

This review concerns an emerging area of nutritional research that has potential implications in preventing cardiac health disease and promoting further benefits of consuming cheese and fermented dairy products.

Vitamin K is the name given to a group of fat-soluble vitamins which comprise vitamin K1 (phylloquinone), vitamin K2 (the term for the range of menaquinones, MK4-13) and vitamin K3. While the role of vitamin K in blood coagulation has been well recognised for many years, it is only recently that a role in cardiovascular health potentially via reducing vascular calcification has been proposed. Vascular calcification describes the accumulation of the mineral hydroxyapatite in the arterial wall and is linked to an increased risk of heart disease.

While data on the vitamin K content of dairy foods are limited, many kinds of cheese contain high concentrations of K2 forms. Recent clinical studies have shown that K2 (MK-7) can inhibit vascular calcification. The review suggests that the protective effects of cheese against coronary heart disease, despite the saturated fat content, may be due in part to its vitamin K2 content.

Apart from the further clinical studies required to confirm the role of K2 forms in protecting coronary arteries, the review indicates the need for additional research to determine vitamin K concentrations in fermented dairy products.

- Details

The taxonomy of the genus Lactobacillus has been revised and species previously designated as lactobacilli have been designated into 25 genera including the emended Lactobacillus genus.

Researchers publishing in the International Journal of Dairy Technology (IJDT) should check the standing of the genus of any Lactobacillus species they are citing using the tool at http://lactotax.embl.de/wuyts/lactotax/ . Sanders and Leeber (2020) have provided a list of important genus changes for probiotic lactobacilli on the IAAP website, please see https://isappscience.org/new-names-for-important-probiotic-lactobacillus-species/ that authors may find particularly helpful.

Lactococcus lactis subspecies cremoris was elevated back to the species level as L. cremoris by Li et al. (2019) refer to https://www.microbiologyresearch.org/content/journal/ijsem/10.1099/ijsem.0.004727. These nomenclature changes are being implemented by the IJDT.

- Details

Students often need to calculate the percentage change in the initial or start and final values of numbers for e.g. microbial populations, acid degree values in foods, body weight. In this situation the order of the numbers used in the calculation is important and the change can be negative or positive. This calculator enables this change to be calculated.

The percentage difference calculator finds the absolute value (regardless of sign) of the change in value for any two numbers that belong to the same category. The calculator can be accessed from this link.

- Details

The International Journal of Dairy Technology is pleased to announce the appointment of an additional five renowned dairy scientists/technologists to the Editorial Board of the Society of Dairy Technology (SDT) journal, the International Journal of Dairy Technology (IJDT).

The new members are Profa. Verônica Ortiz Alvarenga, Universidade Federal de Minas Gerais – UFMG, Brazil; Prof. Hamid Ezzatpanah, Islamic Azad University, Iran; Dr Ehsan Moghaddas Kia, Maragheh University Of Medical Sciences, Iran; Dr Ahmed Olowo-Okere, Usmanu Danfodiyo University, Nigeria and Dr Diarmuid (JJ) Sheehan, Teagasc Food Research Centre, Ireland.

Further information on the remaining members of the Editorial Board is available at https://onlinelibrary.wiley.com/page/journal/14710307/homepage/editorialboard.html.

The IJDT is published by Wiley on behalf of the SDT.

- Details

Volume 75, Issue 1 (February 2022 issue) of the International Journal of Dairy Technology introduced a new feature, the Editor’s Choice Article. This has been selected as a paper whose content has global potential for cost-effective adoption or significantly adds to the science and technology of milk processing.

The February article selected is ‘Development of global fatty acid models and possible applications’ by Daniel Schwarz, Marie Rosenberg Bak and Per Waaben Hansen. This represents the result of a collaboration between FOSS Analytical A/S and the Faculty of Science, Copenhagen University.

The authors have used advancements in Fourier transform infrared (FTIR), which is a commonly applied technology in milk analysis, to enable high-throughput determination of milk fatty acid (FA) profiles. The reviewers, in particular, noted that ‘FTIR is a research tool to look for new relationships between the FAs in milk with milk production and processing characteristics’ and that it is ‘a relatively rapid and cost-effective way of creating additional insights that could be used to optimise dairy chains from farm to consumer when added to existing data and knowledge’.

The authors conclude that the prediction of FA using FTIR technology opens up the possibility to routinely test raw milk for FA profiles in a cost-effective way and utilise the resulting data for different purposes including the production of dairy products with enhanced concentrations of desired FA, improving and optimising dairy farm management and economics.

The article can be freely accessed for 30 days at https://doi.org/10.1111/1471-0307.12820.

- Details

This is an interesting video on density measurement by Mettler Toledo. Towards the end of the video the presenter introduces the company's digital density meter. This is an interesting and important innovation in density measurement. However it is expensive.

- Details

Four new calculators have been added to the ice cream mix calculator at www.dairyscience.info/calculator1 . The calculators added are :

• Calculator for determining the the effects of temperature and storage time on the growth of ice crystals in ice cream

• Calculate the approximate titratable acidity and pH values for ice cream mixes containing 7–13% milk solids-not-fat (MSNF)

• Predict the density of cream at temperatures between 3 and 30 °C knowing the the fat concentration

• Predict the density of cream at 9.85 °C from the fat concentration

- Details

Dr Saumya Bhaduri a distinguished molecular biologist has contributed a guest-post on the Covid-19 pandemic.

- Details

The article "Equivalent time temperatures between 80° and 90°C for the pasteurisation of ice cream mixes" has been updated and now considers the recommended minimum processing conditions in Canada, New Zealand, the US and the UK. See here.

- Details

IJDT Associate Editor Professor B Mehta is coordinating a national webinar on "Trends in detection of adulterants in milk and ghee".

- Details

A good text book is even better if you can send questions to the author and get a timely response. I have recently found a really good process engineering book written by Arun Datta an author who responds to queries! The book is accompanied by Excel spreadsheets containing VB script that enables the solution of complex problems. Arum Datta is a consulting process engineer with extensive industry experience.

In Process Engineering and Design Using Visual Basic, Arun K. Datta provides a unique and versatile suite of programs along with simultaneous development of the underlying concepts, principles, and mathematics. Each chapter details the theory and techniques that provide the basis for design and engineering software and then showcases the development and utility of programs developed using the material outlined in the chapter. This all-inclusive guide works systematically from basic mathematics to fluid mechanics, separators, overpressure protection, and glycol dehydration, providing basic design guidelines based on international codes. Worked examples demonstrate the utility of each program, while the author also explains problems and limitations associated with the simulations.

For more information see Process Engineering and Design Using Visual Basic® - 2nd Edition - Ar (routledge.com).

- Details

The editorial group of Wiley is offering Assistant Editor positions based in their Beijing or Shanghai offices for their internationally-renowned food science and nutrition journals, including Molecular Nutrition and Food Research. As part of an international team of editors, the focus of this role is on evaluating manuscripts, handling peer review and making decisions on which manuscripts to accept for publication. Link removed

- Details

Despite global food standard agencies consistently advising consumers against the consumption of raw milk, demand for the sale of raw drinking milk (RDM) continues. Milk-borne pathogens are of public health concern because they can cause a range of diseases including bovine tuberculosis, brucellosis, Q-fever, campylobacteriosis, haemolytic-uremic syndrome, salmonellosis, listeriosis and tick-borne encephalitis. These illnesses may range in severity from mild diarrhoea to severe disease and even death.

Dr Giuseppe Aprea and Dr Michael Mullan (Aprea and Mullan, 2021) in a book chapter entitled “Raw milk: benefits and hazards”consider why some consumers, despite well-publicised information on health risks, continue to advocate drinking raw milk and discusses the natural indigenous antimicrobial and antiviral factors, beneficial bacteria in milk, the risks to consumers from RDM and how these might be mitigated.

- Details

|

UCC ICE CREAM SCIENCE AND TECHNOLOGY COURSE 8th -10th March 2022 University College Cork, Ireland |

|

|

This intensive three-day course provides participants with knowledge of the science and technology of all frozen desserts, both dairy and non-dairy, including ingredients, processing and quality aspects. Lectures are complemented with demonstrations and there are ample opportunities for personal contact with the trainer and industry colleagues. This course, similar to that delivered at the University of Guelph, Canada, is very popular with participants from around the world and places fill very quickly. |

|

Who should attend?

|

|

This course is given by Professor Douglas Goff, a Professor in the Department of Food Science, University of Guelph, Canada. He is well known in Canada and internationally for his research work in ice cream science and technology and has published and presented numerous book chapters and over 150 scientific and technical papers in this area to both scientists and to dairy personnel. Further information on the course content is available here. |

- Details

Pasteurised milk is sold with a use-by-date which means it should not be consumed after that date for food safety reasons. From time to time it has been suggested that the use-by-date should be replaced with a best-before-date partly to reduce food wastage.

Nathan Devlin, a final year honours degree student at CAFRE’s Loughry Campus has investigated the microbiological quality of commercial HTST milk produced by two commercial plants in Northern Ireland at the use-by-date. All samples were stored at 3°C.

Nathan Devlin, a final year honours degree student at CAFRE’s Loughry Campus has investigated the microbiological quality of commercial HTST milk produced by two commercial plants in Northern Ireland at the use-by-date. All samples were stored at 3°C.

Several jurisdictions have regulations for microbial limits in pasteurised milk with the Grade “A” Pasteurized Milk Ordinance (PMO) in the US well known. This sets a total count limit of 20,000 cfu/ml and a maximum of 10 coliform/ml in pasteurised milk. Other jurisdictions tend to use higher total counts and replace coliforms by typically <10 cfu/ml of Enterobacteriaceae. Limits for Bacillus cereus are also included in some jurisdictions.

Nathan found that > 85% of the samples analysed failed the PMO standard for the total count and >27% of samples failed the EU limit of <10 cfu/ml of Enterobacteriaceae at the use-by-date. No issues were found with the counts of B. cereus.

Based on the results, Nathan recommends that a use-by-date for pasteurised milk is maintained and that further work is undertaken to identify and control the post-process contamination that is responsible for the results found.

Nathan Devlin can be contacted at nathan.d123@hotmail.co.uk .

- Details

Submissions are invited to three Special Issues of the International Journal of Dairy Technology (IJDT).

Special Issue: "Novel alternatives to traditional thermal processing in dairy manufacturing."

For further information go to https://onlinelibrary.wiley.com/page/journal/14710307/homepage/Special-issue-novel-alternatives. Professor Gomes da Cruz can be contacted at: food@globo.com

Special Issue: "Structure of milk and milk products: effect on functionality, digestibility, nutritional value, and health properties."

For further information go to https://onlinelibrary.wiley.com/page/journal/14710307/homepage/Special-issue-milk-structure. Professor Mehta can be contacted at: bhavbhuti5@yahoo.co.in .

Special Issue: "Cheese: Advances in understanding the cheese matrix and its influence on structure-function relationships, metabolic activity of entrapped microbiota, health properties, and ripening characteristics."

For further information go to https://onlinelibrary.wiley.com/page/journal/14710307/homepage/Special-issue-cheese. Dr. Sheehan can be contacted at diarmuid.sheehan@teagasc.ie .

- Details

Two new calculators have been added. These are intended to help students undertake population surveys and to calculate the margin of error of surveys that have been undertaken.

• How do you choose a sample size for a survey?

• How do you calculate the margin of error in a statistical sampling scheme?

- Details

A PDF on how to write your first paper for the International Journal of Dairy Technology (IJDT) can be accessed at https://onlinelibrary.wiley.com/journal/14710307. A copy can be downloaded from here.

A PDF on how to write your first paper for the International Journal of Dairy Technology (IJDT) can be accessed at https://onlinelibrary.wiley.com/journal/14710307. A copy can be downloaded from here.

- Details

A PDF on how to write your first paper for the IJDT can be accessed at https://onlinelibrary.wiley.com/journal/14710307. A copy can be downloaded here

- Details

The most important route of Mycobacterium avium subsp. paratuberculosis (MAP) transmission in cattle, is fecal-oral and milk is regarded as an important vehicle for MAP transmission to dairy calves. Pamela Steuer and her colleagues at the Universidad Austral de Chile working with Michael T. Collins, University of Wisconsin Madison School of Veterinary Medicine, have studied the efficacy of treatments for milk being fed to calves as a means of preventing MAP infection transmission.

The study was a one-year longitudinal study and was carried out on a Chilean dairy farm. New-born calves were assigned to one of four experimental groups. Five calves received naturally MAP-contaminated milk. For comparison, 5 calves received the same milk after treatment with copper ions, 4 calves were fed commercial calf milk-replacer and 3 were fed UHT treated milk. MAP concentrations were estimated for copper-treated and untreated milk. Infection progression was monitored monthly. After one year, calves were euthanized, and tissue samples were cultured and visually examined.

The authors found that MAP was undetectable in calf milk replacer and UHT milk. Copper ions treatment significantly reduced the number of viable MAP in naturally contaminated milk. Fecal shedding of MAP was observed in all study groups, but the group of calves fed untreated, naturally contaminated milk began to shed MAP earlier than the rest.

Pamela Steuer and her colleagues concluded that strict dependence on a single intervention to block infection transmission, no matter how important, may fail to control this insidious infection on dairy farms. To be successful, paratuberculosis control programs must use multiple methods to interrupt infection transmission between the source, MAP-infected adult cows, and the most susceptible animals on the farm, young calves.

This article can be downloaded as a preprint from https://doi.org/10.21203/rs.3.rs-72767/v1 . This preprint is under consideration at BMC Veterinary Research.

- Details

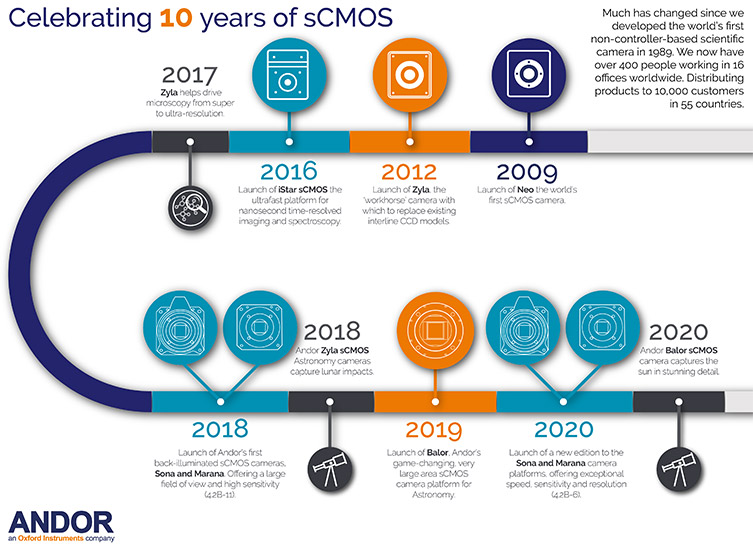

Andor Technology are running a virology conference on the 23 - 24 March 2021. The conference will feature food-related bacteriophage topics as well as current mammalian virus presentations on for example the SARS-CoV-2 virus.

There are a number of interesting food related presentations include one by Dr Cath Rees on how to use bacteriophages to enumerate pathogenic bacteria. Dr Giuseppe Aprea will discuss molluscs as potential vectors for the transmission of the SARS-CoV-2 virus. The latter presentation will be of interest to anyone who consumes uncooked shellfish!

I have previously mentioned research on mask wearing and the effectiveness of masks in reducing the spread of virus aerosols from those infected with COVID-19. Interestingly one of the researchers, Alan Giltinan, Chief Technical Officer & Senior Researcher, BCO, Cork, Ireland will be reviewing his work at the conference.

Registration is free and you can register here.

- Details

A calculator that enables the concentration of lactulose to be predicted after a single, defined heat treatment using 3-algorithms developed by Browning et at. (2001), Claeys et al. (2003) and Rombaut et al. (2002) has been added to the website. All algorithms use the Arrhenius rate equation but use slightly different values for activation energy (E). Note that a value of E = 122 kJ/mol has been used in the algorithm reported by Browning et at. (2001).

This compliments the calculators in the article "Ultra-high-temperature (UHT) processing of milk. Process lethality, chemical effects and use of temperature-time-integrators (TTIs) to predict heat treatment and over-processing".

- Details

NI Science Festival runs from the 15 - 28 February 2021. One of the companies presenting is Andor Technology.

In the presentation, Dr Alan Mullan Product Specialist for Microscopy Cameras at Andor Technology discusses how Andor's products are being used to diagnose COVID-19 and research the SARS-CoV-2 virus. This presentation will not be highly technical and is accessible to all.

Andor Technology is a world leader in the design and manufacture of high-performance scientific imaging cameras, microscopy and spectroscopy systems. Andor Technology is based in Belfast.

- Details

Not all postgraduate students find it easy to write their first research or review paper.

Working with Camilla (Millie) Preece I have produced a guide for first time authors. A draft version of the guide in the form of a PowerPoint presentation can be accessed here. The guide is currently being formatted by Wiley and will be available on the International Journal of Dairy Technology website for viewing and download. Millie Preece is a PhD student from Harper Adams University in the UK.

- Details

The International Journal of Dairy Technology (IJDT) has moved fully Online.

The IJDT has seen many changes since its inception as the Journal of the Society of Dairy Technology in 1947. For the last 20 years, the IJDT has been published both Online and in print‐copy. In common with other journals, demand for the print version has been reducing, and following consultation, it has been decided to move fully Online from February 2021.

This move will enable the Society of Dairy Technology which does not charge page fees, working with Wiley, to continue to provide a highly ranked, leading international dairy journal. This change will also reduce both our carbon footprint and the costs of production thus keeping our subscription and other charges competitive with other journals.

The February edition can be accessed at https://onlinelibrary.wiley.com/toc/14710307/2021/74/1 .

- Details

The Ice cream mix calculator has been updated and is back OnLine. The updated calculator can calculate mixes using multiple fat and MSNF inputs, sucrose, dextrose and fructose inputs, CSS and variable mix weights.

The calculator uses the linear algebra package for Java called Jama. Jama is available from https://math.nist.gov/javanumerics/jama/ . The calculator produces a matrix of inputs and uses a range of mathematical decomposition scripts to solve the matrix. This works well for ice cream mixes.

- Details

Evidence is increasing that asymptomatic carriers of Covid-19 release large quantities of virus laden aerosol droplets. Despite it being apparently obvious that the wearing of face masks by asymptomatic carriers and infected people would reduce air-borne virus loads, this is not universally accepted.

Recent work by researchers in Ireland has clearly shown, in simulated experiments, that mask wearing markedly reduces the release of aerosols.

Image “Talking heads” copyright owner Blackrock Castle Observatory, Cork

The Talking Heads image produced by a team of researchers from Blackrock Castle Observatory, CAPPA and CIT has won Science Foundation Ireland’s Research Image of The Year Award 2020. The image was produced by researchers investigating the effectiveness off mask materials at preventing the spread of aerosol droplets. The MASK (Making Aerosol Safety Known) project was funded under SFI’s Covid-19 Rapid Response Funding Call.

This research clearly shows that wearing a masks can make a difference. Using a mask greatly reduces the number of aerosol droplets emitted into the environment, thus potentially reducing the risk of Covid-19 transmission.

More information on this research and other current research topics can obtained from the Andor Technology Learning Centre .

- Details

A new calculator that enables conversion between the major pressure units, pascal, kilopascal, bar, millibar, pounds per square inch (psi) and standard atmosphere used in practice has been added.

- Details

Microscopes are very complex pieces of equipment, that have evolved to accommodate many different imaging techniques. Microscopy and its applications have promoted many key breakthroughs in life

- Details

Plant proteins e.g. pea, rice can easily be used in meat, stews, pies without too much difficulty but are challenging to use in ice cream manufacture particularly at >3% protein. Off-notes, gritty texture and mouthfeel are the major issues. These increase as protein level increases.

- Details

The article on how to derive an equivalent heat process at a higher (or lower) temperature given a reference time and temperature assumes knowledge of the thermal constant z. A further article on how to calculate z given two different but equivalent thermal processes has been added.

- Details

An article on how to determine temperature/time combinations in order to meet the minimum processing conditions to meet the US Grade A Pasteurized Milk Ordinance (2017) has been added to the web site.

- Details

Thermal Processing Training Course

University College Cork

4 & 5 November 2020

- Details

A new calculator that enables the conversion of the major methods for measuring the titratable acidity of milk and milk products has been added. For the first time a free On-Line calculator that enables conversion between Soxhlet Henkel degrees, Thörner degrees, Dornic degrees and percentage lactic acid milk titratable acidity measurements is available.

- Details

The article on the "Reliability of microbial sampling in assuring food safety and calculation of prevalence following negative tests" at

https://www.dairyscience.info/index.php/food-model/275-sampling.html has several calculators one of which calculates the number of samples required to meet a microbiological specification. The author has made the code for this calculator freely available. The code can be downloaded at https://www.dairyscience.info/index.php/202-uncategorised-sp-269/378-asp-code.html .

- Details

Three new calculators to help with microbial sampling statistics have been added to the website.

• Calculate probability of detecting a pathogen

• Calculate the number of samples required to test to meet a food standard

• Calculate the prevalence of a pathogen in a food that has tested negative after analysis

- Details

I have updated an article on food sampling and microbial testing following a book chapter that I have been writing on raw drinking milk (RDM). Recent changes in legislation in the UK require critical pathogens to be absent in 25 ml of RDM and in the absence of a Critical Control Point particular emphasis is being placed on microbiological testing to ensure safety. This article consider the distribution of microorganisms including clusters in foods and the limitations of testing are discussed. The economic and public health significance of clustering is illustrated by the meticulous work of Jongenburger et al. (2011). These workers investigated why a consignment of powdered infant milk formula (PIM) produced in Europe (the batch of approximately 22,000 kg was produced in 3 shifts) was rejected because of contamination with Cronobacter spp. by the importing Chinese authorities. Jongenburger et al. (2011) sampled 31 bags close in production time to the bag that tested positive for Cronobacter spp. in China using multiple samples (2290) and found 8 positive samples from 3-bags. The article also considers the question: assuming that all the samples taken for testing are negative, what might the probable prevalence of a pathogen or fault-causing organism in a food be? Interactive calculators to determine the statistical significance of sampling schemes and the effect of sample numbers and mass on prevalence are provided. The article is available at https://www.dairyscience.info/index.php/food-model/275-sampling.html .

- Details

Please give a thought to the scientists who are doing the research and testing for SARS-CoV-2 virus in Italy and elsewhere. Like the front line doctors and nurses we all owe them our thanks and best wishes at this difficult time.

Readers may recall previous mentions of Dr Giuseppe Aprea. Dr Aprea, a veterinary graduate from the University of Naples, studied for part of his PhD on lactic bacteriophages with the author in Northern Ireland.

Giuseppe is currently a Veterinary Manager Officer for the Istituto Zooprofilattico Sperimentale dell'Abruzzo e del Molise "Giuseppe Caporale" (IZSAM). Until recently his research was mostly related to the detection of foodborne viruses and bacteriophages. IZSAM is a public health institute with administrative and managerial autonomy, which operates as a technical and scientific arm of the Italian state and the Abruzzo and Molise Regions in Italy.

On March 13, the IZSAM of Teramo joined the Covid19 network in the Abruzzo Region and is performing the official analysis of human swab samples for SARS-CoV-2 virus, the causal agent of Covid-19. Abruzzo is situated in central Italy and has around 1000 confirmed Covid-19 cases to date.

Dr Giuseppe Aprea and colleagues at the Istituto Zooprofilattico Sperimentale dell'Abruzzo e del Molise.

The first phases of the analytical processes are carried out in a BSL4 mobile laboratory with high biological containment. In the maximum safety laboratory, the analysts work on 4 daily shifts. PCR analyses are performed by a group of 20 people, working in couples, on six shifts per day, in order to be able to process >400 samples per day.

Dr Aprea has been involved since the 23rd of March in the real time PCR analysis of the swabs and is personally processing over 100 samples per day. Currently some 30% of the samples tested are positive for the virus.

- Details

We expect a lot from Marks and Spencer. Rightly so, they also expect high standards from their suppliers. However, the M&S response to Covid-19 as evidenced by their failure to protect all their bakery items in their in-store bakeries is disappointing.

I was surprised to get an Email from a former student a few days ago saying that unpacked bakery items were on display in a Marks and Spence store in Northern Ireland. I was surprised since the major mechanism for spreading the SARS-CoV-2 virus, the virus that causes Covid-19, is aerosol droplets produced from infected people that are present in the air. Infection occurs when we breathe in the droplets, touch surfaces where the droplets have landed or eat food contaminated by these droplets.

Electron micrograph of SARS-CoV-2. Copyright NIAID.

Today I went into my local M&S in Cookstown and yes the bakery had lots of bakery items, unpackaged and potentially exposed to contamination by the the SARS-CoV-2 virus. I mentioned my concerns to a staff member whose immediate reaction was "that's what we have always done!". Obviously this needs to change.

Selection of bakery items at local Marks and Spencer store on the 20th March 2020. Note many are not packaged.

Statutory HTST pasteurisation has minimal effects on the major antimicrobial proteins in bovine milk

- Details

For the last month or so I have been writing a chapter on the advantages and disadvantages of drinking raw milk for a new dairy science/ technology book. Because of my interest in modelling I have been modelling the denaturation or loss of biological activity of the major humoral and non-specific antimicrobial proteins. I have provided access to a free OnLine calculator that will enable those interested to do their own calculations. IgA is the most sensitive of the Igs in milk to heat and the calculations indicate minimal loss of activity after 72 °C for 15 seconds (statutory HTST pasteurisation of milk). To use the calculator the Decimal reduction time of the biological factor or quality factor is required e.g. 319 seconds for IgA at 72 °C. See https://www.dairyscience.info/newcalculators/ig.asp . More in the future.

- Details

Over the last 10-years or so there have been major developments in imaging technology e.g. it now possible to view components in living cells at high resolution. These developments have arisen through advances in technology, sensors in particular, staining techniques and off course software.

One of the companies that has been responsible for some of these developments is Andor Technology, Andor is now part of Oxford Instruments. Andor have recently provided a series of articles on developments in imaging technology. See below. The science content of these articles is high and they are ideal for undergraduate and postgraduate teaching.

- CRIPSR and Gene Editing – Designer Genes

- Optogenetics – Illuminating the Inner Processes of the Brain

- Organoids – Providing a More Accurate Model of Complex Cell Function

- Super Resolution – What’s Happening Beyond the Diffraction Limit?

- Light Sheet – Is it all about the Beams?

- Expansion Microscopy – An Alternative Approach to Higher Resolution Imaging

- Adaptive Optics – Correcting Distortions to Enhance Resolution

- Clearing Tissues – Providing Clarity on Brain Function

- Deep Learning – Applying Machine Learning to Help Solve Complex Questions

- Dragonfly – High Speed Multi-modal Confocal System

- Details

Following my recent interview by Drs Aleks Marsh and Alan Mullan (my son) of Andor Technology about the pasteurisation of milk. Alan and Aleks turned the interview into a podcast which is now live. Listening to my responses I realize that I am not a natural for TV or radio and that I am fortunate to be retired! The article on MAP can be downloaded free from Researchgate.

- Details

Dr Mark Tamplin, the Director of Combase, has announced new data for Salmonella in low moisture foods:

- Salmonella in peanuts (Park et al., 2008)

- Salmonella in x-ray treated almonds and walnuts (Jeong et al., 2012)

- Salmonella in moist-air convection treated almonds (Jeong et al., 2009)

- Salmonella in hot water treated almond kernels (Harris et al., 2012)

- Salmonella in peanut butter and peanut butter spread (Burnett et al., 2000)

- Salmonella in oil roasted almonds (Abd et al., 2012)

- Salmonella in chamomile, peppermint, and green tea (Keller et al., 2015)

- Salmonella in wheat flour (Smith and Marks, 2015)

- Details

Following my recent article "Are we closer to understanding why viable cells of Mycobacterium avium subsp. paratuberculosis are still being reported in pasteurised milk? (https://doi.org/10.1111/1471-0307.12617)" I agreed to do a Podcast with Dr Aleks Marsh and Dr Alan Mullan of Andor Technology in an attempt to explain some of the questions that the general public might have about pasteurisation. The Podcast will be broadcast on the 16 January 2020 and is available from the "The Good, the Bad and the Curious" webpage at the Andor website.

- Details

I have agreed to write an article on raw milk as part of a series of chapters in a new book produced by Elsevier that will be published in 2020. I will cover the antimicrobial factors and other topics including the presence of probiotic bacteria in modern hygienically-produced milk. The safety of raw milk for human consumption, particularly for children, will also be included.

One of the points I want to make is how easy it is for milk to become contaminated and how difficult it is to prevent some forms of contamination. I am trying to source photographs showing dirty 'drinkers', birds and rodents in/on cattle feed e.g. Total Meal Replacement (TMR), dirty udders, dirty cows.

Below are some of the images that I have found/ obtained or been given so far.

The photograph below shows starlings (a major pest and potential carrier of many human pathogens) eating components in the TMR fed to dairy cows. Farms are not operating theatres and farmers live in the real world. Hence we need to use all the options at our disposal to reduce risk e.g. pasteurisation.

Image from: Anon. (2013) Practical Control Strategies for Starling Infestations. Report prepared for DairyCo by Kingshay. Download url:https://dairy.ahdb.org.uk/non_umbraco/download.aspx?media=16123 .

A further picture clearly showing the nuisance value of starlings in a dairy farm in the US.

Image kindly provided by Professor Amber Adams Progar, Department of Animal Sciences, Washington State University.

Boetech (2019) has claimed that "half of the cows (in Europe) are drinking dirt and shit" I am trying to get some images of cow faeces in drinkers.

Below is a typical picture of crows perching on a water trough in a field. Bird faeces in outside water troughs is not uncommon and are an obvious source of E.coli and other pathogens.

Picture courtesy of Aidan Brennan Irish Farmers Journal

- Details

A beta version of a calculator that uses the results of a titration with NaOH to calculate the % lactic acid, Soxhlet Henkel degrees, Thörner degrees, Soxhlet Henkel degrees and Dornic degrees of a milk sample has been added. Users may vary the molarity of the NaOH solution, note normality and molarity are identical for NaOH, and the volume of milk used. An accompaning tutorial that provides the underpinning science remains to be added.

- Details

The article "Isolating lactic acid bacteria from milk" has been updated following queries why controls are required using M17 agar to selectively enumerate Streptococcus thermophilus in environments containing L. delbrueckii subsp. bulgaricus. While many strains of L. delbrueckii subsp. bulgaricus are inhibited by the β-glycerophosphate in M17, Shankar and Davies (1977) found that 23% of the strains of L. delbrueckii subsp. bulgaricus tested grew well on this medium. Hence the need for controls to confirm colonies as S. thermophilus.

- Details

There is considerable interest in alternatives to thermal processing. A recent review in the International Journal of Dairy Technology by Ahmad and his colleagues looks at the effects of non thermal processes on the activity of milk enzymes. I have included the abstract below.

Impact of nonthermal processing on different milk enzymes. Ahmad et al (2019) Available at https://doi.org/10.1111/1471-0307.12622.

Abstract

Milk is highly perishable and deteriorates rapidly during storage. Although the thermal processing technologies successfully inactivate many enzymes and microorganisms up to a required level, they can negatively affect the natural flavour of dairy foods and decrease their nutritional value. Alternative nonthermal technologies have been established as an interesting approach to produce safe and healthy dairy products, without compromising their nutritional quality. These techniques have the ability to inactivate milk enzymes without affecting the milk quality. In addition, the combination of two different nonthermal techniques and mild heating has proven to be more effective to provide safety to milk when compared to the treatments alone. This review aims to evaluate the impact of nonthermal technologies, in particular, ultrasound, pulsed electric field, high‐pressure processing and ultraviolet irradiation on milk enzymes.

- Details

Despite the extensive research on the effects of low temperature storage of milk on the quality and yield of cheese, cheese companies continue to experience periodic problems due to milk being stored for several days on farms. Below is an abstract of some research published in 1994. It is as relevant today as then!

Abstract

Milk stored at 3°C and 7°C was used to manufacture cheese and the quality and yield of cheeses were assessed. Storage of milk at both temperatures resulted in reduced yields. Storage at 7°C for 3 or more days and 3°C for 5 days adversely affected cheese quality while storage at 3°C for 3 days resulted in an improvement in quality. There was a significant correlation between cheese quality and the psychrotrophic count and total viable count (TVC) of the raw milks. Evidence indicated that the reduction in quality was largely due to the action of extracellular lipolytic enzymes produced by psychrotrophic bacteria. It was concluded that milk for Cheddar cheese manufacture should have a TVC of < 1 x 106 cfu/ml and preferably a count of < 1 x 105 cfu/ml.

Reference

Weatherup,W. and Mullan,W.M.A. (1993) Effects of low temperature storage of milk on the quality and yield of cheese. Proceedings of IDF Seminar on Cheese Yield and Factors Affecting Its Control, Cork, Ireland, pp. 85–94.

See also https://www.dairyscience.info/index.php/cheese-yield/354-effect-of-storing-milk.html .

- Details

My article on why we are still finding viable cells of Mycobacterium avium subsp. paratuberculosis (MAP) in pasteurised milk has been published On Line ahead of print. Details are given below:

Mullan, W M A (2019) Are we closer to understanding why viable cells of Mycobacterium avium subsp. paratuberculosis are still being reported in pasteurised milk? International Journal of Dairy Technology. Access is available at https://doi.org/10.1111/1471-0307.12617 .

- Details

The Dairy Industry Student Award is sponsored by The Society of Dairy Technology.

This award recognises the efforts of new entrants to the Dairy Industry and promotes their talent to a wide audience. The work of the winning individual will be communicated to a global audience, showcasing their achievement. The award will be presented at the prestigious trade lunch (on the Tuesday of the ICA) at the Nantwich International Cheese Awards in July 2019.

The award is open to any student studying a food science and technology course in the United Kingdom or the Republic of Ireland. Courses may be vocational qualifications, diploma, degree and so on. There is no age restriction to applicants; however the student must be undertaking a dairy project or be employed within the dairy industry.

ALL submissions must be electronically submitted in both PDF and Word formats and NOT as a hard copy. It should be emailed to execdirector@sdt.org by May 30th and judging will take place during June.

- Details

There is relatively little information on the diversity of Polish cheeses. Professor Marek Kosmulski has decided to change this and has published a book detailing some 600 Polish cheeses. This is available free as a download. The book, in Polish, consists of a series of brief descriptions of each cheese accompanied by photographs. Using Google Translate it is relatively easy to get a good understanding of the major attributes of each cheese. The book can be downloaded from http://bc.pollub.pl/dlibra/publication/13557 .

- Details

Arguably one of the most significant scientific development's in the last 10 years has been the development of an unique gene editing technology that can be applied to whole cells called CRISPR/Cas9. This technology has many applications in biomedical research, including the potential to treat human genetic disease. However, the technology also has the potential to modify the human genome and change human society.

One of the best free videos explaining how the technology works and giving the background to the discovery is given in the animation below produced at the McGovern Institute for Brain Research, MIT where Professor Feng Zhang, a leader in the development of this technology works.

Further information can be found on Professor Zhang’s website.

- Details

Two calculators for determining equilibrium moisture values corresponding to selected Aw values using the Guggenheim–Anderson–de Boer (GAB) model and the Brunauer-Emmett-Tellet (BET) model have been added.

To use the models, the constants for the product concerned must be inputted. Selected Aw values are then added. The calculator will then calculate the equilibrium moisture content for each value and plot it against Aw, to give a sorption or desorption isotherm.

- Details

Ireland has a well-deserved reputation as a global leader in food innovation and it is fitting that a new world food resource, bia-biz.com, was recently launched by Michael Creed, the Irish Minister for Agriculture, Food and the Marine.

bia-biz.com is a comprehensive online directory of valuable technical content and free training for food producers, entrepreneurs, scientists, technologists and advisers.

Reflecting the complexity and knowledge needed in today’s food and beverage industry bia-biz.com has 13 pages, 130 sections over 2000 web links, 73 free online trainings, a global events calendar and a national regulations and support page for 112 countries. The layout, site-plan and search functionality is intuitive and user friendly.

- Details

There have been several updates to the Dairy Science and Food Technology website in May, 2018.

- An article on how to use Excel to make a calculator for determining the F value of a heat process has been added and can be accessed at https://www.dairyscience.info/index.php/thermal-processing/304-excel-spreadsheets.html .

- A range of Excel Spreadsheets for calculating F, B*, C* values of thermal processes and thermal processing indicators can be downloaded. These can be accessed at https://www.dairyscience.info/index.php/thermal-processing.html .

- The article "Dry heat sterilisation and depyrogenation" has been updated to reflect the biphasic nature of the destruction of pyrogens particularly at temperatures below 180 °C. Access is available at https://www.dairyscience.info/index.php/thermal-processing/238-dry-heat-sterilisation-and-depyrogenation.html .

- Details

The article "Factors affecting plaque formation by bacteriophages" has been updated to reflect research by Luhtanen et al., 2018* on cold-active phages.

*Luhtanen,A.-M.,Eronen-Rasimus,E., Oksanen,H.M., Tison,J.-L., Delille,B.,Dieckmann,G.S.,Rintala,J.-M. and Bamford,D.H. (2018). The first known virus isolates from Antarctic sea ice have complex infection patterns. FEMS Microbiology Ecology, 94, 4, 1-15. (available from https://doi.org/10.1093/femsec/fiy028).

- Details

The author with chemist colleague Ronnie Irvine visited The Echlinville Distillery at Rubane, just outside Kircubbin, in the Ards Peninsula. A brief account of our visit to Ireland's newest whiskey distillery is given here.

- Details

Six new site calculators have been added.

Three are concerned with determining holding tube length, average holding time and Reynolds number:

• Calculator for determining Reynolds number

• Calculator for determining average holding time in a pasteurizer or UHT holding tube

• Calculator for determining holding tube length in pasteurizing and UHT plant

Following feedback from users of data loggers a unique highly flexible F value calculator designed to work with thousands of pasted values of time -temperatures has been added. This calculator allows users, for perhaps the first time, to compare F values obtained by numerical integration using the industry standard method, the trapezoid rule with the more accurate Simpson's 1/3 and 3/8 rules:

A calculator for predicting the concentration of HMF, lactulose and furosine in heated milks (whole, semi-skim and skimmed milk) that also calculates the F0, B* and C* values and the destruction of thiamine has been added. The calculator has been designed to work with thousands of pasted values of time -temperatures. The values are integrated using the industry standard method, the trapezoid rule, and are compared with the more accurate method of numerical integration, Simpson's 1/3 and 3/8 rules:

• Calculator for predicting the concentration of HMF, lactulose and furosine in heated milks (whole, semi-skim and skimmed milk). It also calculates the F0, B* and C* values and the destruction of thiamine. The values are integrated using the industry standard method, the trapezoid rule, and are compared with a more accurate method of numerical integration, Simpson's 1/3 and 3/8 rules.

A generic F calculator for UHT and similar high temperature processes has been added. The calculator has been designed to work with thousands of pasted values of time-temperatures. The values are integrated using the industry standard method, the trapezoid rule, and are compared with the more accurate method of numerical integration, Simpson's 1/3 and 3/8 rules

• Calculator for determining the lethality (F, B* values) and chemical changes (C* value) for UHT processes using the trapezoid and Simpson's rules. Applicable to all UHT processes and designed to take thousands of pasted values.

- Details

A free article, "Ultra-high-temperature (UHT) processing of milk. Process lethality, chemical effects and use of temperature-time-integrators (TTIs) to predict heat treatment and over-processing" has been added to the Dairy Science and Food Technology website.

This article investigates how to calculate the lethal effects of UHT treatment and the usefulness of TTIs for differentiating sterilised, direct and indirectly processed UHT-treated milk. The importance of accessing accurate temperature time-data and knowing holding tube dimensions, flow rate, average and minimum holding time and the flow characteristics (Reynolds number) are discussed. The reliability of a model developed by Claeys et al. (2003) to predict the effects of UHT-processing on hydroxymethylfurfural, lactulose and furosine concentrations in milk is discussed. Free On Line calculators for calculating holding time, average flow rate, holding tube length in UHT and HTST plants are provided. A free On Line calculator programmed using the thermal constants calculated by Claeys et al. (2003) is provided to calculate hydroxymethylfurfural, lactulose and furosine concentrations following heat treatment in skim, semi fat and full fat milks. This calculator also calculates F0, B*, C* and % destruction of thiamine. Two methods of numerical integration are used to measure the cumulative lethal and chemical effects of UHT treatment, namely the Trapezoid and Simpson's rules.

This article investigates how to calculate the lethal effects of UHT treatment and the usefulness of TTIs for differentiating sterilised, direct and indirectly processed UHT-treated milk. The importance of accessing accurate temperature time-data and knowing holding tube dimensions, flow rate, average and minimum holding time and the flow characteristics (Reynolds number) are discussed. The reliability of a model developed by Claeys et al. (2003) to predict the effects of UHT-processing on hydroxymethylfurfural, lactulose and furosine concentrations in milk is discussed. Free On Line calculators for calculating holding time, average flow rate, holding tube length in UHT and HTST plants are provided. A free On Line calculator programmed using the thermal constants calculated by Claeys et al. (2003) is provided to calculate hydroxymethylfurfural, lactulose and furosine concentrations following heat treatment in skim, semi fat and full fat milks. This calculator also calculates F0, B*, C* and % destruction of thiamine. Two methods of numerical integration are used to measure the cumulative lethal and chemical effects of UHT treatment, namely the Trapezoid and Simpson's rules.

The article can be viewed at https://www.dairyscience.info/index.php/thermal-processing/325-uht-processing.html .

- Details

This website gets a lot of Email and occasionally one connects.

According to the Daily Mail as many as 9.75 million people - 15 per cent of the UK population - are believed to have been hit by flu symptoms this week. Some 120 flu deaths have been recorded in England, 21 are known to have died in Scotland and eight in Northern Ireland.

It was against this background that a reader who works for a major food processing company sent me a picture of unpackaged bakery-items completely exposed to the environment at a food retailers with a global reputation for producing safe food. She was surprised that the retailer was not taking action to prevent contamination of their bakery items with airborne viruses and from customers with virus-contaminated hands.

- Details

The article on "Factors affecting plaque formation by bacteriophages" has been updated and can be accessed at

Plaques of phage D29 produced by Mycobacterium avium spp paratuberculosis assayed using Mycobacterium smegmatis. Image courtesy of Dr Irene Grant, Queens University Belfast.

- Details

Lactic starter cultures have a well-deserved reputation for inhibiting, and or in some instances killing, spoilage and pathogenic bacteria not just in dairy foods but in meat and vegetable products also.

While the importance of undissociated lactic acid as an inhibitor of the growth of pathogens by starters has been known for many decades it is only recently that the effect has been quantified for Listeria monocytogenes in Gouda cheese.

- Details

Fat agglomeration is affected by the process parameters used in gelato and ice cream manufacture, the emulsifer stabiliser system and ingredients. Fat agglomeration has a significant role in dryness of extruded ice cream, slow meltdown, good shape retention and resistance to shrinkage during storage. Too much protein can result in an over stable fat emulsion and insufficient fat agglomeration.

A calculator to determine the maximum MSNF compatible with normal fat agglomeration has been added and can be accessed here.

- Details

The latest forum post concerns raw milk and A2 milk. The posts can be viewed at https://www.dairyscience.info/forum/where-to-buy-raw-milk-in-uk_topic454.html .

- Details

There is a legislative requirement in most developed countries for food companies to have validated-HACCP plans for all products. The current E.coli 01507:H7 outbreak in Scotland has been linked to raw milk cheese and the death of one child has been reported. Note there are few examples of well validated HACCPs even from large companies!

There are a number of published risk assessements for raw milk cheeses. One of the most comprehensive, "Microbiological Risk Assessment of Raw Milk Cheese", has been produced by Food Standards Australia /New Zealand using quantitative models developed by the University of Tasmania. The assesment can be downloaded from https://www.foodstandards.gov.au/code/proposals/documents/P1007%20PPPS%20for%20raw%20milk%201AR%20SD3%20Cheese%20Risk%20Assessment.pdf .

- Details

Recent deaths associated with the consumption of lettuce and other salad vegetables have been well publicised in the media. How do you advise parents to respond to the risks associated with eating salads and maintain consumption of healthy foods? And would this advice differ if they had an immunocompromised family member? Perhaps you have a view on my response to a query from a parent? Please see http://www.dairyscience.info/forum/preparing-salads_topic432.html .

- Details

Is Thermus thermophilus the causal agent of pinking in cheese?

“Pinking” the development of a red / pink colour in many cheese-types has been known for many years and has been the attention of significant research interest for decades. Much of this research has been inconclusive although some association with lactobacilli has been suggested.

Recently Quigley et. al. (2016) used shotgun metagenomic sequencing to reveal the presence of bacteria corresponding to three phyla, Firmicutes, Actinobacteria, and Deinococcus-Thermus in 8 ‘continental’ cheeses exhibiting pinking. The phylum Deinococcus-Thermus was absent in control cheese.

- Details

I purchased one pot of fat-free-natural yoghurt produced by a major dairy company from the Asda supermarket in Cookstown a few days ago. I opened it this lunchtime today (12th June). It had a use before date of the 24th June 2014 (see below).

I noticed the lumps, clumps of curd on the lid immediately. See below.

Looking at the inside of the container the top part of the yoghurt was less viscous than the bottom, syneresis was starting and grains/lumps/nodules were clearly visible.

The grains / nodules can be clearly seen on the spoon images below.

It is always interesting to see how companies respond to problems. No one answered the contact phone number given on the carton. I also completed a web form on the company website and attempted to contact their PR company using the information on their website. The contact information was not correct however I managed to get the correct information from their website. I eventually got a response of sorts from the website form.

This is the second time in a month that I have bought a stirred yoghurt with this fault. The first time was from a local company in Northern Ireland and it was a natural yoghurt made with whole milk.